What is chemical etching and how does it work?

There are teams of engineers grappling with the manufacture of new products and applications who will be asking themselves the question, “which metal machining process is the best fit for our requirements?” The answer is not always straightforward, as the geometries and characteristics of the part to be manufactured will vary and so will the best fit manufacturing technology.

Choosing the right technology will be affected not only by the type of metal being processed, but also by its thickness, the required quality of cut, and the speed with which the manufacturing operation needs to be completed.

Ultimately, however, there are some givens when it comes to process selection. Cost per part and quality are key and fairly universal drivers, and the customer is judge and jury when assessing the success of the manufacturing technology finally selected.

What is chemical etching?

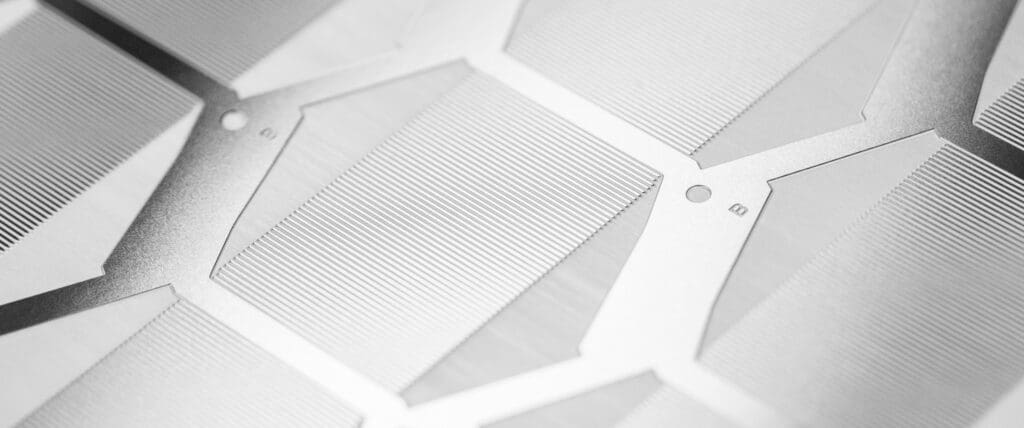

Chemical etching is a metal processing technology that produces stress-free, flat components by selective etching through a photo-resist mask. It is especially well suited to the manufacture of precision parts such as grids and meshes, lead frames, bipolar fuel cell and plate heat exchangers, precision springs, washers and gaskets and decorative parts such as automotive interior trim.

The etching process step by step

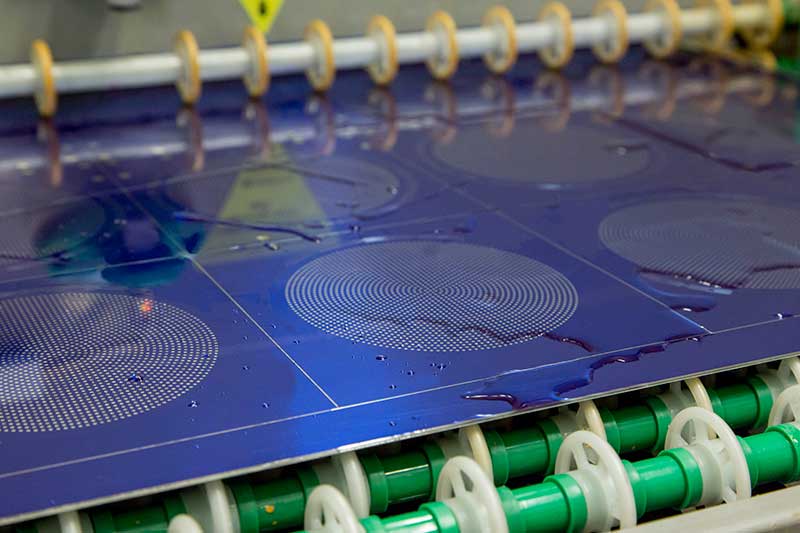

- First, sheet metal is cleaned then laminated with photoresist, a light-sensitive polymer

- The photoresist is then exposed to UV-light which transfers the CAD image of the component

- Areas of unexposed resist are removed (developed) to reveal the raw metal

- The sheet is sprayed with etchant chemistry, selectively removing the unprotected metal

- The remaining photoresist is removed (stripped) to reveal the final etched component

Advantages vs. traditional sheet metalworking

When compared with conventional production processes, chemical etching has a number of inherent advantages, key among which are the ability to produce parts without degrading material properties, the fact that there is almost no limit on part complexity, and the ability to process a huge range of metals and alloys.

Metals suitable for etching includes:

- Austenitic, ferritic and martensitic steels

- Coppers, brass and nickels

- Hard to machine metals such as titanium and aluminium

- High-temperature alloys such as Inconel

When looking at each of the conventional processing technologies, each suffers from a number of drawbacks, such as the degradation of the material being processed due to high impact, or in the case of laser cutting the use of intense heat. However, the other key differentiator is in the area of tooling, which can be illustrated by comparing chemical etching to stamping. The tooling for chemical etching is digital, so there is no need to start cutting expensive and difficult to adapt steel moulds. This means that large quantities of products can be reproduced with absolutely zero tool wear, ensuring that the first and millionth part produced are precisely the same.

Also, as the tooling is “virtual”, it can be adapted and changed extremely quickly and economically, making it ideally suited for anything from prototype runs to high volume production runs. This allows for design optimisation without financial penalty, and helps ensure a low-risk entry strategy as well as facilitating easy product updating. Turnaround time using photo-tools is about 90% less than that for stamped parts. Stamping requires substantial investment in mould fabrication which is not only costly but in some instances can take from six to ten months to complete, compared with a few hours for etching.

<blockquote”>

The tooling for chemical etching is a key stimulus to design freedom, along with the ability to produce what may seem like impossibly complicated products

Design freedom

The economy and adaptability of the tooling for chemical etching is a key stimulus to design freedom, along with the ability to produce what may seem like impossibly complicated products. The cost of creating prototypes is low and there is no barrier to entry with the technology, with complex designs being produced in a matter of days and designs iterations in a few hours. Perhaps the key drawback for industry in general is that in many instances, chemical etching is not part of some engineers’ repertoire, and because of this innovation can be somewhat stunted. Chemical etching opens the door for innovation and pushes back the barriers that constrain many design engineers and allows for the manufacture of parts many thought impossible.

Complexity without cost

Many of today’s products are extremely complex and also very fragile. Geometric complexity and the requirement for extremely exacting tolerances and precision mean that chemical etching is not just “a” potentially desirable manufacturing process, but is, in fact, the “only” technology able to make certain products.

Let’s take a closer look at the complexity conundrum.

Typically, when stamping, part complexity adds cost, whether in low, medium, or high volume applications. The complexity of a product means the necessity for a complex mould tool, and complex tooling means increased costs, increased potential for tool failure, and increased lead-times for satisfactory completion. Chemical etching is unaffected by the level of tool complexity, and it makes no difference in terms of costs or lead-time how complex the geometry of the part is and therefore the complexity of the digital tooling.

Chemical etching has the ability to produce finer detail than is possible with stamping, and all with minimal if any degradation and deformation of the metal being processed and little to no likelihood of burrs or defects. Failure rates are minute, and unlike in the stamping process, every part produced is absolutely flat, which in some application is absolutely vital.

Of course, stamping does have its place. Whereas chemical etching’s “sweet spot” is in the manufacture of complex parts in small to medium-sized production runs, in extremely high volume runs where the tooling expense is justifiable, and where designs are not overly complex, stamping typically represents a more economic process.

In essence, stamping produces a product by pressing a substrate into a mould. Chemical etching is an altogether more complicated process, hence its ability to be applied to complex geometries and to achieve exacting levels of precision.

Chemical Etching Whitepaper

Learn how chemical etching can overcome the limitations of traditional sheet metal machining technologies.

Download